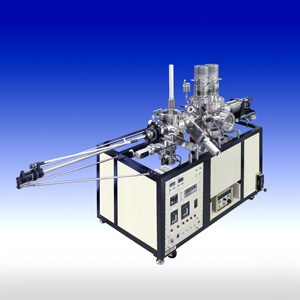

Sputtering System

Sputtering System is a kind of thin film depositing apparatus in which energetic ions hit on target materials to sputter out the material atoms, and the atoms reach the substrate and are deposited on. An advantage of this depositing method is that it can be applied to high melting point materials deposition at relatively low temperature, metal alloys, metal oxide dielectrics, insulants and others.

Tokyo Institute of Technology, National Institute for Materials Science, National Institute of Materials Science, and National Institute of Advanced Industrial Science and Technology

| Estimate |

| Sputtering System |

|

* Our company can design and provide the system according to the customers' specifications. For details, click here to contact us.

|

|

4"Magnetron Sputtering Source

|

|

| Estimate |

| Magnetron Sputtering Deposition System |

|

This System is an ultra-high vacuum planar magnetron sputtering system using DC magnetron sputter guns. It is equipped with a rotational substrate holder with cooling function, which enables uniform deposition without heat damage. At most three targets can be inserted for multi-layer deposition. Its design is based on human-factors engineering; for example the good usability of sample / tip transporting and the internal locking for safety use.

| Vacuum rage |

< 1.0 E-9 Pa |

| Substrate temperature |

Max 500℃ |

| Sample transfer |

Transfer rod operation |

| Sputtering control |

Emission or sweep control |

- Sputtering deposition chamber

- Sample stage operating mechanism

- Sample cooling system

- Shutter operation mechanism

- Load lock chamber

- Sample transfer mechanism

- Sputtering power controller

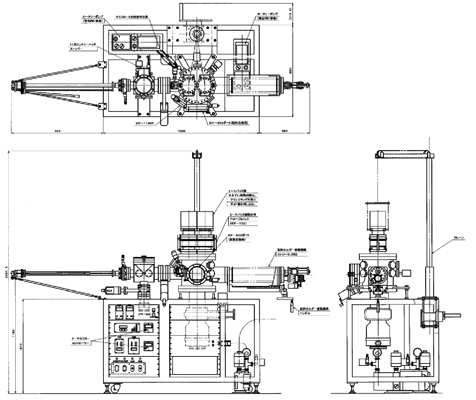

This system is a planer magnetron sputtering system equipped with four magnetron sputtering sources. It can be operated at ultra-high vacuum due to the uniquely designed load-lock mechanism of Kitano. The rotary substrate stage gives good uniformity in thickness and good material quality, and the sample cooling mechanism prevents the samples from the heat damage. At most four sputtering sources for multi-layer deposition are available. This system is designed as a multi chamber system with scalability and can be easily connected to your present apparatus in use.

- All the components of the system except vacuum gages can be repeatedly baked above 200℃.

- Designed as an ultra-high vacuum system and the leak level is less than 1.33×10-11Pa・m3/sec (measured with a He leak detector).

- The molybdenum sample holder supports 2 inch sample in diameter.

- Using the Kitano transfer rod (option), the sample holder can be manually and safely transported to the sample fixation stage.

- The trestle has casters and its height is adjustable.

- The system will be designed according to the selected sputtering gun.

- High vacuum chamber

| Feature size |

ICF-356-NSp/203/152/114/70 |

|

| Port |

ICF-203, ICF-152, ICF-114, ICF-70 |

| Material |

SUS316L |

| Surface finish |

Buffing + electro-chemical polishing mirror finish |

| Out-gassing treatment |

Vacuum baking 450℃ for 48 hours |

| Leak built-up |

5 X 10-11Pa・m3/sec |

| Vacuum range |

<<1x10-11Torr (with cooling shroud at Liq.N2, turbo molecular pump of 300 l/sec and ion-pump l/sec) |

- Three axis manipulator

| Z-movement |

100mm up/down KUD-114/100Z motor-drive |

|

| R-movement |

360 degree rotational platform KMRP-114 motor-drive |

| Tilt-movement |

90 degree up/down KUD-114/70SP motor-drive |

- Motor-drive controller

Motor-drive controller by stepping motor (with controller box)

- Sample heating stage

| Sample holding |

Pin down with nail plates |

| Temperature |

Max 1200℃ |

| Heater material |

Ta heater on Mo holder

Rotary joint connector |

- 下部フランジ

| 形状 |

ICF-356/152x4/70x1 |

|

| ポート |

ICF-203、ICF-152、ICF-114、ICF-70 |

| 材質 |

SUS316L |

| 表面処理 |

複合電解研磨鏡面仕上げ |

| 高温処理 |

真空ベーキング 450℃?48時間以上 |

| リーク量 |

5x10-11Pa・m3/sec |

- 液体窒素シュラウド

| 材質 |

ステンレス316L |

|

| 方式 |

液体窒素溜め込み式(8/3"パイプ使用) |

| 処理 |

バフ研磨鏡面仕上げ、ヒートサイクル処理(10回) |

| リーク量 |

5x10-8Pa・m3/sec |

- メインシャッター機構

| 方式 |

トランスファーロッド方式(オプション/モーター駆動) |

|

- 膜厚センサー移動機構

| センサー |

水晶振動子(オプション) |

|

| 取付フランジ |

ICF-70 |

| 移動距離 |

100mm(精度0.1mm) |

- 架台

| 材質 |

SS材/焼付塗装処理(黒色) |

| 寸法形状 |

600x1200x1500

キャスター・アジャスター付き |

- ユーティリティー

| AC100V |

単相 30A |

| AC200V |

三相 20A |

| 圧縮空気 |

5kg/cm2 |

| 冷却水 |

循環水使用(1次側工事は含まれておりません) |

| Estimate |

| Four Source Magnetron Sputtering Deposition System |

|

* Our company can design and provide the system according to the customers' specifications. For details, click here to contact us.

|

Home > Products|Thin film formation equipment|Sputtering system

Home > Products|Thin film formation equipment|Sputtering system